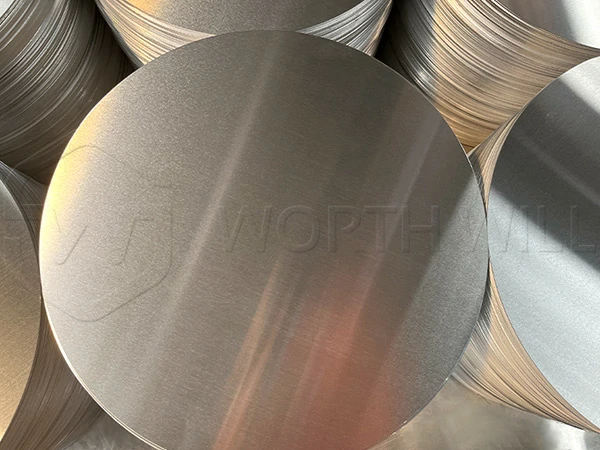

Aluminum Circles

- Home

- Aluminum Circles

Aluminum Circles are a versatile metal that plays a crucial role in various industries due to its exceptional properties. One of its lesser-known but equally important forms is the aluminum circle.

Types of Aluminum Circles

Pure Aluminum Circle: These circles are made from 100% pure aluminum. They have highly corrosion-resistant. Often used in applications where corrosion resistance is essential, such as in the food industry for cookware like pots and pans.

Aluminum Alloy Circle: Created by combining aluminum with other elements like copper, magnesium, or silicon. This alloying process enhances specific properties of the metal, such as strength and durability. Alloy circles are widely used in the automotive and aerospace industries for manufacturing parts and components.

Anodized Aluminum Circle: Anodization is a process that creates a protective layer on the surface of aluminum, making it more resistant to corrosion and wear. Anodized aluminum-circle are often used in decorative and architectural applications due to their enhanced durability and appearance.

Coated Aluminum Circle: Coating aluminum circles with materials like Teflon or ceramic can provide non-stick properties, making them ideal for cookware like frying pans and baking sheets. In applications where resistance to chemicals.

Embossed Aluminum Circle: These circles have textured patterns or designs on their surface, which not only enhances their aesthetic appeal but also improves grip in certain applications. They are commonly used in the manufacturing of decorative items and signage.

Uses of Aluminum Circles

Cookware and Kitchen Utensils: Widely employed in the production of cookware, including pots, pans, and baking sheets, due to their excellent heat conductivity and even distribution. Their durability and resistance to corrosion make them a preferred choice in the culinary world.

Automotive and Aerospace Industries: Used in the manufacturing of various components for vehicles and aircraft. Including wheels, engine parts, and structural elements. Their lightweight nature helps reduce overall vehicle weight, improving fuel efficiency.

Electronics: They are used in the production of electronic enclosures and heat sinks. Their ability to dissipate heat efficiently ensures that electronic devices operate at optimal temperatures, preventing overheating.

Construction and Architecture: Anodized and coated aluminum circles find applications in architectural structures, curtain walls, and decorative elements. They offer durability, weather resistance, and aesthetic appeal, making them a popular choice for modern buildings.

Signage and Decorative Items: Embossed aluminum circles are commonly used for creating eye-catching signage, nameplates, and decorative items. The textured surface adds visual interest and enhances the overall appearance of these products.

What Is Aluminum Circle?

Aluminum circles, available in various types and alloys, are a versatile and indispensable material in many industries.

Their remarkable properties, including corrosion resistance, durability, and lightweight nature. It makes them an ideal choice for a wide range of applications, from cookware to aerospace components and architectural design.

Understanding the types of this product and their uses can help businesses and consumers make informed decisions when choosing this valuable material for their specific needs.