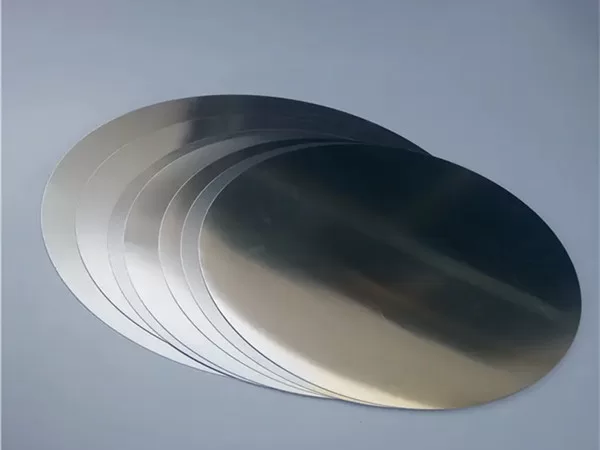

1100 Aluminum Circle

- Home

- 1100 Aluminum Circle

1100 aluminum circle is a versatile material that finds its way into numerous industries, thanks to its excellent properties such as lightweight, corrosion resistance, and malleability. Among various aluminum alloys, 1100 circle stands out as a popular choice due to its unique properties and applications.

What is 1100 Aluminum Circle?

1100 aluminum is a commercially pure aluminum alloy, primarily composed of aluminum and a small percentage of other elements like copper, iron, and silicon. When this alloy is formed into circular sheets or discs, it becomes a 1100 aluminum circle. The manufacturing process typically involves processes like rolling, stamping, and cutting.

Applications of 1100 Aluminum Circle

Cookware: One of the most common applications of 1100 aluminum circles is in the cookware industry. Due to its excellent thermal conductivity, 1100 aluminum circles are used to make various kitchen items such as pots, pans, and cookware lids. Their ability to heat up quickly and distribute heat evenly makes them perfect for cooking.

Lighting Industry: Extensively used in the production of lighting fixtures. Their malleability allows manufacturers to create intricate designs, and the reflective properties of aluminum enhance the illumination quality. The 1100 alloy is particularly suitable for this purpose because of its high electrical conductivity.

Signs and Nameplates: The corrosion-resistant nature of 1100 aluminum makes it an ideal choice for outdoor applications like signage and nameplates. It can withstand exposure to the elements without rusting, ensuring longevity and readability.

Reflectors: Frequently used to create reflectors in various lighting applications. Whether in streetlights, automotive headlights, or industrial fixtures, these circles provide efficient light reflection.

Chemical Industry: The corrosion resistance of 1100 aluminum circles also makes them suitable for chemical processing applications. They are used in tanks, vessels, and other equipment that handle corrosive substances.

General Fabrication: Widely used in general fabrication for their ease of machining, forming, and welding. They find applications in a range of industries, including construction, automotive, and aerospace, where lightweight and durable components are essential.

Advantages

Corrosion Resistance: 1100 aluminum is highly resistant to corrosion, making it an excellent choice for outdoor and corrosive environments. This quality extends the lifespan of products made with 1100 aluminum circles.

Lightweight: Aluminum is inherently lightweight, and 1100 aluminum circles are no exception. This property is advantageous in various applications, as it reduces the overall weight of the final product without compromising strength.

Good Thermal Conductivity: The high thermal conductivity of 1100 aluminum circles makes them ideal for cookware and lighting applications, ensuring even heat distribution and efficient energy use.

Malleability and Formability: 1100 circles are easy to form and shape into desired configurations. This property allows manufacturers to create intricate designs and customized products.

Electrical Conductivity: In the lighting industry, the high electrical conductivity of 1100 aluminum circles is a significant advantage, ensuring efficient energy transfer in electrical components.

How To Find Right 1100 Aluminum Circles?

1100 circles are versatile, highly reliable, and ideal for a wide range of applications.

Their corrosion resistance, lightweight nature, and excellent thermal conductivity make them a top choice in industries like cookware, lighting, and signage.

Whether you’re in the market for durable cookware or reliable lighting fixtures, 1100 aluminum circles prove their mettle, providing excellent performance and longevity.