Aluminum Round Blank

- Home

- Aluminum Round Blank

Aluminum Round Blank, often underestimated, are essential components in a wide range of industries.

Applications

Industrial Manufacturing: Aluminum round blanks serve as the foundation for various industrial components, including gears, shafts, and flanges. And their exceptional strength and corrosion resistance make them a top choice in heavy machinery and equipment manufacturing.

Aerospace: The aerospace industry relies heavily on precision-engineered aluminum round blanks for creating critical parts like landing gear components, engine mounts, and structural elements. In addition The lightweight nature contributes to fuel efficiency and overall aircraft performance.

Automotive: Aluminum round blanks find applications in the automotive sector, they are very suitable for producing components such as suspension parts, engine mounts, and transmission components. Their lightweight properties aid in reducing vehicle weight, improving fuel economy.

Electronics: In the electronics industry, precision is paramount. Creating connectors, heat sinks, and other intricate components that require tight tolerances and excellent heat dissipation properties.

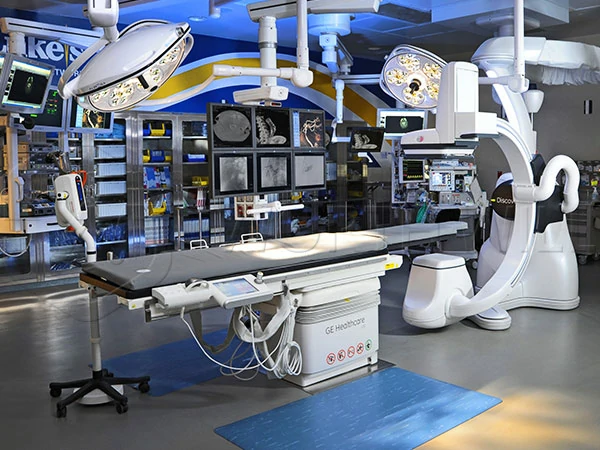

Medical Devices: Medical equipment manufacturers often use aluminum round blanks to craft precise and hygienic components for various devices, including surgical instruments, prosthetic limbs, and diagnostic equipment.

Construction: Aluminum round blanks are a versatile choice for construction applications. They could create structural elements, handrails, and decorative architectural features. Also their corrosion resistance ensures longevity in outdoor environments.

Advantages

Precision Tolerance: Aluminum round blanks can be offer a help about precising tolerances, ensuring consistency and accuracy in critical applications.

Lightweight: Aluminum’s low density makes round blanks an ideal choice for weight-sensitive industries, such as aerospace and automotive, where reducing overall vehicle weight enhances efficiency.

Corrosion Resistance: Aluminum’s natural oxide layer provides excellent corrosion resistance, extending the lifespan of components exposed to harsh environmental conditions.

Machinability: Aluminum is easily machined, allowing for complex and intricate designs, making it suitable for various applications.

Recyclability: Aluminum is 100% recyclable, promoting sustainability and reducing environmental impact. Recycled aluminum maintains its quality and properties, making it an eco-friendly choice.

Packaging Solutions

Packaging is crucial to protect the integrity of aluminum round blanks during storage and transportation. Effective packaging solutions include:

Protective Wrapping: Aluminum round blanks can be wrapped in protective materials like plastic or foam to prevent surface damage and scratches during transit.

Custom Crates or Boxes: For larger or more delicate blanks, custom crates or boxes provide additional protection against physical damage and moisture.

Palletization: For bulk shipments, placing round blanks on pallets and securing them with strapping or shrink-wrap helps ensure safe handling and transport.

Anti-Corrosion Packaging: In environments where corrosion is a concern, using anti-corrosion packaging materials like VCI (Volatile Corrosion Inhibitor) bags or films can prevent oxidation and corrosion during storage and transit.